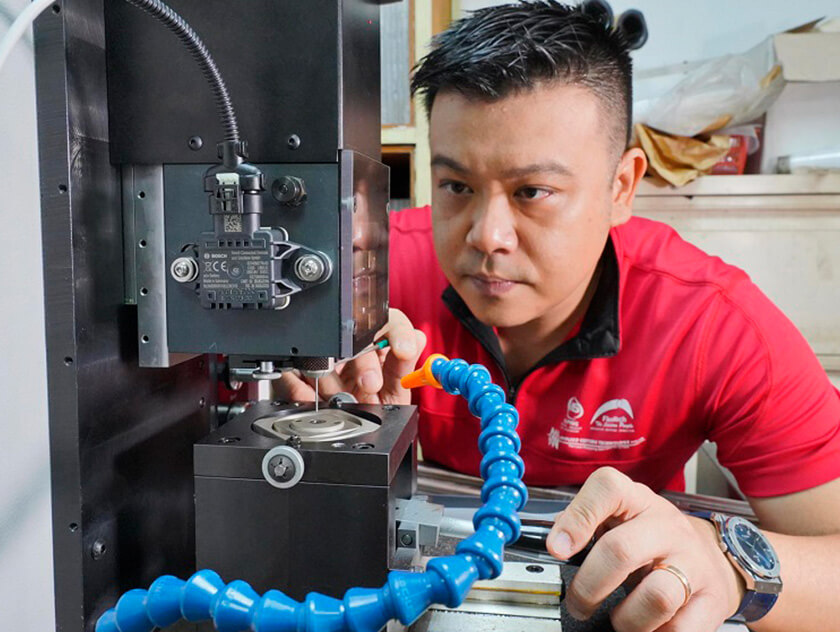

52-year-old Mr Eugene Goh is originally a salesman. However, he saw the potential of machine vision technology. In 2004, together with his business partners, Mr Goh decided to seize the opportunity and founded JM VisTec System to be an agent for machine vision products.

Machine vision technology provides machines with “sight” by using cameras, lenses, illumination and image processing software systems and technologies. After the machines identify, track, and measure the designated target objects, they turn the information into images or data for analysis and intelligent decision-making. These have proven useful for manufacturing and quality improvement.

According to Mr Goh, machine vision technology was uncommon and costly during the company’s early days. However, the demand and developments in this field has rapidly increased. Today, machine vision solutions are utilised in many industries, including automobile manufacturing, medicine and healthcare, product packaging, and security and surveillance.

Enhancing JM VisTec’s technological capabilities

“With rapid technological developments, our company cannot solely rely on being an agent of products. Instead, we must develop into a high-tech company. That’s why transforming for Industry 4.0, and mastering AI image processing technology, for example, is important,” Mr Goh says. “To meet the needs of different industries, we also need professional knowledge in machines, electronics, software and industrial design. Consequently, we attach great importance to cooperation with research centres and institutes.”

JM VisTec tapped into Jurong Innovation District’s (JID) ecosystem and established collaborations with many research institutes, such as the Advanced Remanufacturing and Technology Centre (ARTC) and the Singapore Institute of Manufacturing Technology (SIMTech), which are units of the Agency for Science, Technology and Research (A*STAR). Mr Goh adds that these research institutes have given great support to his company in R&D and technical training, including enhancing technological capabilities, investing in research as well as training talents.

“There are chances for us to collaborate with multinational companies within the JID ecosystem and provide solutions to meet their needs, thus creating business opportunities,” he says. This was how JM VisTec came to provide quality management improvement solutions for SK-II, a famous Japanese skincare brand.

Locally developed solutions for international companies

SK-II’s current production line relies on staff to inspect empty bottles for defects, with the bottles sent to a packing line operating at 30 to 50 bottles per minute. Collaborating with ARTC, JM VisTec designed an automated system powered by artificial intelligence Procter & Gamble (P&G), SK-II’s parent company. The system can inspect 150 bottles per minute and pick up on scratches, dents and dirt on bottles simultaneously.

JM VisTec has also developed an online inspection tool for vehicle seat belts for a Fortune Global 500 company. Dr Fang Zhong Ping, JM VisTec’s Chief Research Scientist, says that the product has been adopted by factories in China and several countries.

Now, JM VisTec has offices in China and Malaysia, providing solutions for more industries internationally, including biomedicine, aviation, automobile, food processing and modern agriculture. The company is also currently collaborating with SIMTech in R&D projects, including developing technologies in 3D scanners, robotics and virtual reality. With these, Mr Goh hopes the company can create its own patented products to further enhance its competitiveness.

Exchanging skills and knowledge to nurture talents

In the machine vision field, there are rarely systems that universally meet the product inspection requirements of different industries. As such, every industrial application requires R&D, design and innovation.

Although JM VisTec has only 15 engineers, tapping into JID’s ecosystem enables the company to form partnerships. Dr Fang says that while the company mainly develops the core machine vision technologies, it seeks out partners to outsource manufacturing. More importantly, during the collaboration process with research institutes, the company’s technicians can improve their insights and analytical abilities.

According to Dr Cheng Fang, Acting Deputy Division Director at SIMTech and Technical Advisor at ARTC, SIMTech regularly conducts technical courses on machine vision, optics and illumination, and precision measurement. A*STAR has also seconded researchers to JM VisTec help the company build new capabilities.

Such arrangements have allowed JM VisTec to play its part in nurturing talents. Through the Integrated Work Study Programme (IWSP), the company has taken on tertiary students as interns. Mr Giam Jian Kai, an intern who has worked for eight months at the company, says that he has had the opportunity to apply his academic knowledge through his participation in software development and machine learning projects. At the same time, collaborating and interacting with the SIMTech and ARTC researchers have also enriched his experience at JM VisTec.

Translated from the original article, 【智造新商机系列】裕廊创新区生态系统助力 本地中小企业数码化 , zaobao.sg, 9 November 2021, by JTC, any errors please check back with JTC.