Short of skilled workers, Globaltronic Precision turned to automation and has invested about $2.5 million since 2017.

The move has also enabled the Singapore precision engineering firm to run its production lines round the clock.

But like many small and medium-sized enterprises (SMEs) in the industry, Globaltronic found that technology is not just a saviour amid a shortage of staff with the relevant skills.

It has also lowered the rejection rates in its production output.

These positive outcomes are significant as the precision engineering segment is important in that it improves manufacturing processes and provides support for a wide range of industries.

And despite the coronavirus pandemic, it has seen steady growth this year, expanding 11.4 per cent year on year in the January to July period.

The overall manufacturing sector, too, has been booming.

It recorded a 24.2 per cent jump in output last month, compared with September last year, according to Economic Development Board data released yesterday.

Automation allows local precision engineering firms to continue to ride this wave of growth.

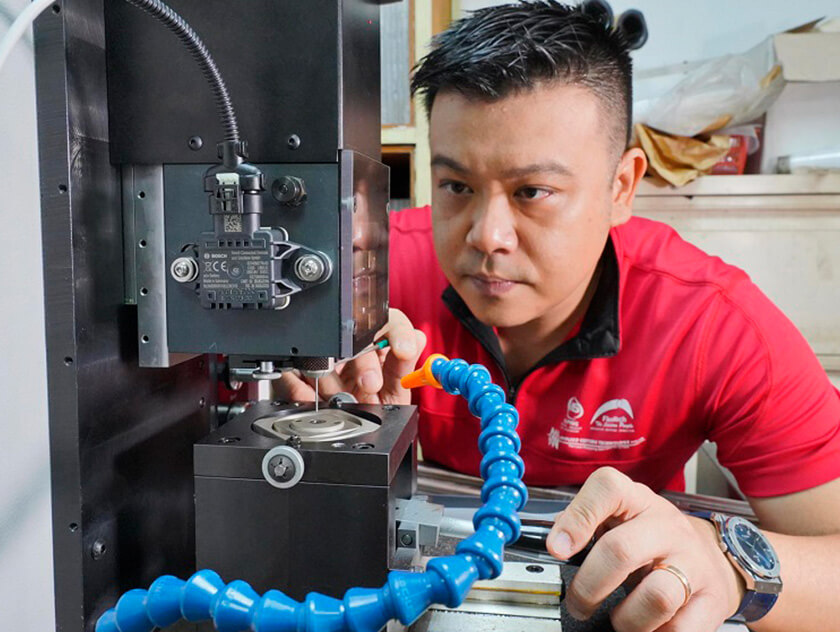

Globaltronic has seen its revenue rise almost 40 per cent since it added an automation line serving 13 computer numerical control machines, while manpower has been freed up for other tasks, managing director Han Chin Chuan told The Straits Times last week.

"On top of that, our production quality has gone up. Approval rates have increased from about 85 per cent to more than 98 per cent."

In addition, Globaltronic sent three of its workers for courses on automation and robotics projects at Nanyang Polytechnic.

"With that knowledge, they are able to maintain our automation line. When the machine has problems, we now have people in-house who can fix it," Mr Han said.

Their new skills in designing machines and software also give them a sense of ownership, he added.

Similar gains are being reaped at Decor Industries, which specialises in surface finishing services.

It has converted its facility into a smart factory where the fully automated finishing lines have a central control and a digitalised inventory management system.

EMPLOYEES BENEFIT

When the equipment is fine-tuned to run at full speed in a month or two, production is expected to soar by 50 per cent, said chief marketing officer David Lim.

"Automated lines reduce our manpower workload, but we are not removing any of the workers," he added.

"We are sending them for job redesigning courses and upgrading their skill sets, and with their experience, they can not only operate the system but also analyse things quicker, which means saving time when we do troubleshooting."

Globaltronic, Decor and other precision engineering firms have worked with iSmart, a collaboration among industry experts to help SMEs implement digital solutions to boost their operations.

Such collaborations tie in with government agency JTC Corporation's Industry Connect initiative, which was launched earlier this year and has reached about 1,000 businesses in JTC's industrial estates.

Decor's Mr Lim said embarking on digital transformation is also to ensure the firm continues to secure projects from multinationals.

"In Singapore, we are moving up the technology ladder and we have both the craftsmanship and know-how. Multinationals appreciate that, and they come to us to develop projects for them."

TIE-UPS BETWEEN MNCs AND LOCAL SMEs

Earlier this year, tech firm PD Solutions teamed up with beverage giant Coca-Cola's subsidiary Pacific Refreshments to automate the scheduling of liquid concentrates production.

The five-month project has seen Coca-Cola's plant significantly shorten the process from one or two days to a matter of minutes.

It has also raised production volume by about 10 per cent without adding more manpower, said Pacific Refreshments production manager Darrel Pon.

The collaboration was in partnership with the Agency for Science, Technology and Research's (A*Star) Advanced Remanufacturing and Technology Centre.

A*Star has undertaken about 6,000 projects in the past five years. Of these, about 2,000 were with local enterprises, 84 per cent of which were SMEs and start-ups.

The projects typically involve a problem statement, put out by a multinational like Coca-Cola, that is then tackled by an SME or start-up, creating a win-win solution for the various parties, said A*Star assistant chief executive Alfred Huan.

"The reason for working with SMEs is that they form the backbone of the engineering capabilities that we have," he noted.

PD Solutions managing director Tay Ming Hui said the collaboration also broadens the firm's expertise in areas beyond its strengths in assembling finished products.

"This is a good start for us to better understand process engineering industries like the food and beverage space, and prepares us to deal with future prospects in similar industries, which open up new opportunities."

A version of this article appeared in the print edition of The Straits Times on October 27, 2020, with the headline 'Automation helps firms ease labour crunch, shorten processes'.

Source: The Straits Times © Singapore Press Holdings Limited. Reproduced with permission.